SCAFPPF

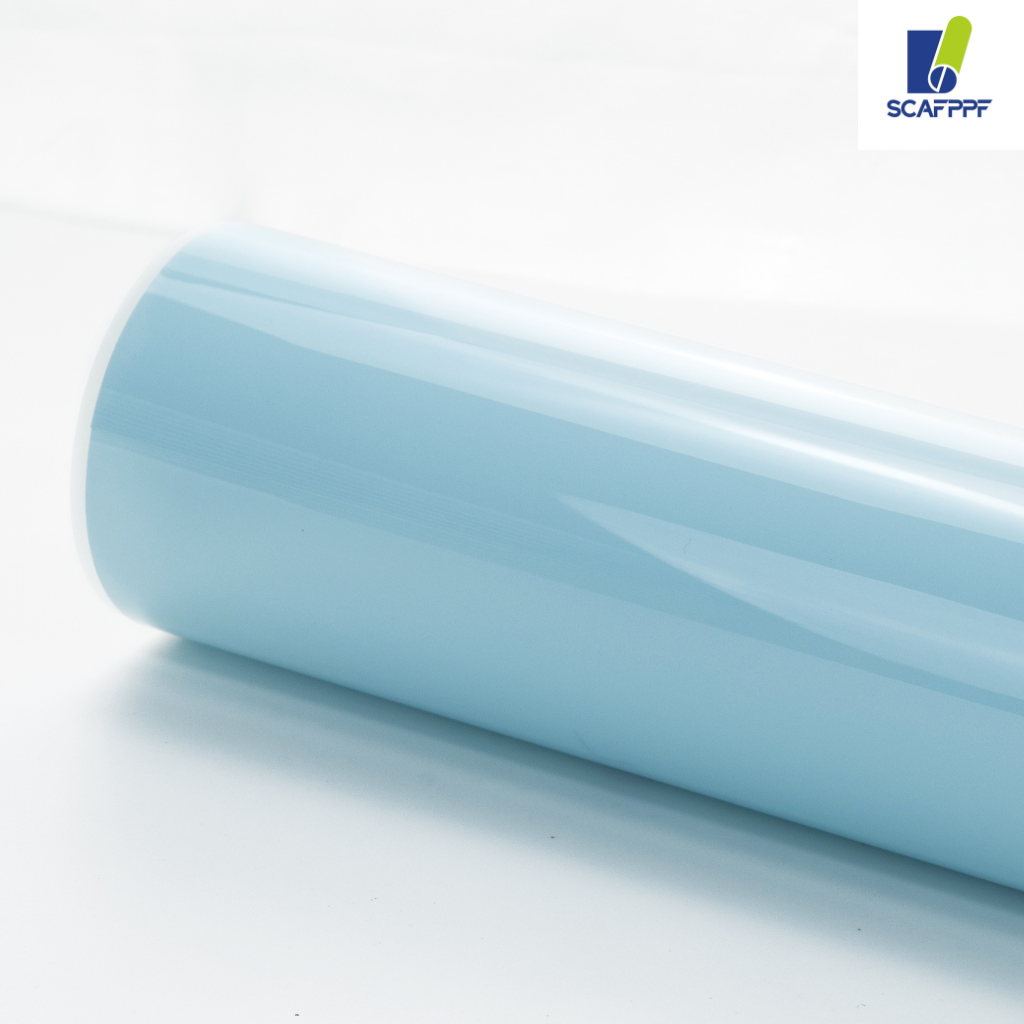

HT Glacier Blue SPC450

HT Glacier Blue SPC450

Couldn't load pickup availability

HT Glacier Blue PPF Wrap – SPC450 CLS-TPU5505L (SG)

Short Description

Transform your vehicle with HT Glacier Blue, a high-performance colored PPF that offers dazzling mirror-like pink tones and advanced surface protection. Built from TPU with a self-healing topcoat, it resists chips, UV damage, yellowing, and contaminants. Ideal for full or accent wraps, this film is as tough as it is beautiful—backed by a limited warranty.

Product Description

HT Glacier Blue is a premium, color-infused protection film (PPF) that delivers both show‑stopping aesthetics and robust surface protection. Part of our Crystal Series colored paint protection film, this film ideal for those who demand both pristine and beauty in loving cars, boats, and home interiors, it offers exceptional long-lasting durability, stain resistance, and UV protection—keeping your surfaces flawless with an invisible finish

Constructed from high-grade thermoplastic polyurethane (TPU) and enhanced with advanced top-coats, the film offers self-healing, hydrophobic, and anti-yellowing properties that maintain its brilliance over time. Get the highest level of protection without sacrificing the look you love.

Key Features

|

Feature |

Description |

|

Crystal Finish |

Embedded crystal flakes produce a mirror-like, light-reflective pink hue that changes subtly with viewing angle. |

|

Self-Healing Topcoat |

Minor scratches, swirl marks, and surface marring can “heal” under heat (sunlight, hot water, heat gun) to restore smoothness. |

|

Hydrophobic / Water‑Repellent Surface |

Repels water, dirt, grime, and contaminants—making cleaning easier and reducing stain buildup. |

|

Anti‑Yellowing / UV Stability |

Engineered to resist yellowing or discoloration over time, even under prolonged UV exposure. |

|

High Impact / Chip Resistance |

Acts as a sacrificial layer to absorb stone chips, abrasions, and road debris to protect the underlying paint. |

|

Chemical / Stain Resistance |

Resists damage from bird droppings, insect acids, road salts, and general environmental contaminates. |

|

High Gloss / Smooth Surface (No “Orange Peel”) |

Smooth, high-gloss finish without textural defects or “orange peel” appearance. |

|

Good Conformability & Stretch |

Allows wrapping around curves, edges, mirrors, seams with minimal distortion or lift. |

|

Clean Removal |

Can be removed cleanly without damaging the underlying paint (when removed properly) if needed. |

Technical Specifications

· Film Type / Base Material: Thermoplastic Polyurethane (TPU)

· Total Thickness: ~ 7.0 mil to 10.0 mil

· Topcoat / Self-Healing Layer: ~ 0.8–1.0 mil

· Adhesive System: Pressure-sensitive, repositionable acrylic adhesive

· Roll Size Dimensions: 1.52 M × 15 M

· Operating Temperature Range: –40 °C to +120 °C

· Elongation / Tensile Strength: 150 % elongation

· Gloss Level: 90+

· Color Stability: 5,000+ hours under accelerated UV test

· Warranty Conditions: Covers yellowing, cracking, delamination (under normal use and installation)

· Life Span: 5-8 years with proper care.

Benefits

· Dual-purpose: Color + Protection — Unlike plain colored PPFs, HT Glacier Blue gives you a dramatic, color-change effect while maintaining full protective functionality.

· Long-Term Durability — Designed to last many years without fading, peeling, or losing optical clarity.

· Low Maintenance — The hydrophobic surface repels contaminants, making washes easier and reducing the risk of stains and etching.

· Restores “New Car Feel” — The mirror-like crystal finish gives vehicles a refreshed, custom look without needing new paint.

· Preserves Underlying Paint — Serves as a sacrificial shield; if needed, it can be removed cleanly, protecting the factory finish beneath.

· Flexibility in Use — Suitable for cars, motorcycles, boats, accent panels, mirror covers, hoods, etc.

· Professional-Grade Installation — Excellent conformability helps installers wrap complex curves, tight edges, and recesses with minimal issues.

Usage & Installation Notes

1. Surface Preparation

o Ensure surface is fully clean, free from wax, sealants, oils, overspray, or contaminants.

o Use isopropyl alcohol (IPA) or a dedicated PPF prep solution on the substrate.

2. Wet-Application Method

o Use a slip solution (water + slip additive) for positioning.

o Once properly placed, squeegee out the fluid and tent the edges.

3. Heat / Annealing

o Use heat (heat gun) to help with conforming over curves, corners, and to reduce stress.

o Gradual heating helps with “healing” the topcoat surface.

4. Edge Sealing

o For long-term durability, edges should be tucked or sealed, especially in harsh environments (marine, high humidity).

5. Curing Period

o Allow adhesive to fully cure (24–48 hours) before exposing to extreme conditions or automated car washes.

6. Cleaning / Maintenance

o Use pH‑neutral, non-abrasive wash soaps.

o Avoid harsh chemical cleaners, strong solvents, abrasive pads.

o Periodic gentle polish or maintenance coat can help preserve gloss but should be mild and safe for PPF.

7. Removal

o When removal is needed, gently heat and peel slowly at a low angle; the film should come off cleanly if conditions were met.

Why Choose Our PPF Wraps?

- Premium-grade TPU film with long-lasting performance

- Easy to apply with excellent stretch & conformability

- Professional look with self-healing technology

- Protects against road debris, oxidation, and discoloration

- Backed by quality and performance you can trust

Share